Customer Focused Solutions

Our approach is simple, utilizing advanced engineering technology to design innovative, efficient, and high-quality products. These air handlers are designed to satisfy diverse building requirements and environments, available in a virtually limitless array of capabilities, configurations, sizes, and capacities

Vertiv™ Energy Labs provides a variety provides a variety of engineering services to support customer’s design efforts. Examples of services include but are not limited to unit design/layout, structural analysis, airflow and thermal analysis, and sound measurement

- Single-point electrical panels

- Chilled water, hot water, steam, or refrigerant piping packages

- A wide variety of energy recovery solutions

- A variety of humidification and dehumidification capabilities

- Integrate third party components and control systems

Very few companies have the breadth of expertise in such a wide range of custom air conditioning disciplines. We have realized innovation through partnership with our customers having demanding requirements, specialized and energy-efficient environments, such as hospitals, universities, schools, performing-arts centers, laboratories, and office buildings.

Our proven willingness and capability to customize air handling products has earned a supreme level of confidence among owners, architects and mechanical engineers, making our systems the chosen design for some of the most prestigious buildings across the U.S.

Design Flexibility

Our approach is simple, utilizing advanced engineering technology to design innovative, efficient, and high-quality products. These air handlers are designed to satisfy diverse building requirements and environments, available in a virtually limitless array of capabilities, configurations, sizes, and capacities

We offer a wide variety of custom components which can be configured into an air handling system to meet any application requirement. Our highly engineered products offer factory options such as:

- Single-point electrical panels

- Chilled water, hot water, steam, or refrigerant piping packages

- A wide variety of energy recovery solutions

- A variety of humidification and dehumidification capabilities

We also take the next step, offering factory installation and integration of control components and systems provided by an independent control manufacturer or integrator. This offers the customer substantial cost savings, as well as the confidence that the unit’s performance and low leakage rate are delivered at the specified level.

Quality Construction

All of our units are engineered and manufactured for durability and long life, providing trouble free performance and energy efficient operation

Each unit features a fully welded, structural base frame, available in conventional painted steel, in stainless steel for caustic atmospheres, such as coastal installations, or in aluminum where corrosion resistance and light weight are required.

Casing panels are offered in 2” and 4” depths, and also come with your choice of galvanized steel, stainless steel, and aluminum materials. Insulation choices include fiberglass, foam, and mineral wool. Casings and bases are offered with a full thermal break.

To ensure the highest quality and compatibility we manufacture critical components including coils, fans, dampers, louvers, and electrical control panels. This unique capability allows us to maintain the highest level of quality while providing the benefits of true single-source responsibility to our customers. An added benefit is the elimination of potential delays and errors caused by component delivery and design issues.

Factory Test Lab

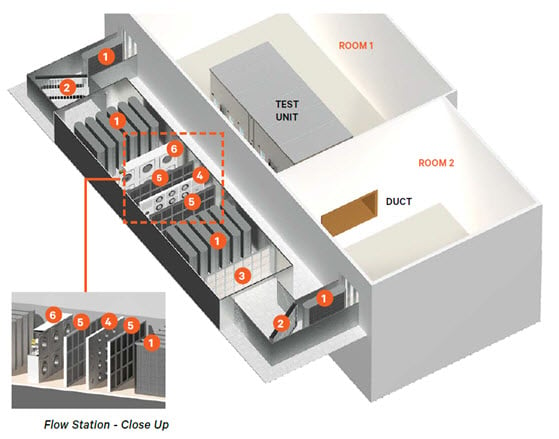

Energy Labs, a Vertiv™ Company, is one of a select few manufacturers with its own state of the art testing facility. This facility, built in 2011, offers simultaneous measurement of airflow, static pressure, power consumption, and inlet and outlet sound power levels, in compliance with AMCA 210 ad 300 standards.

AMCA 210 Air Flow Testing

AMCA 210 Air Flow Testing

Even certified fans don’t always meet performance ratings once installed in an AHU. Space limitations and unique flow path geometries do not replicate the ideal flow patterns that exist in a fan certification test, resulting in altered performance. To ensure that the system will perform exactly as specified, the manufacturer must have accurate and accredited factory testing capability during design, development, and validation of performance after manufacturing is completed.

Factory air flow, sound, and power measurement

Factory air flow, sound, and power measurement

Energy Labs, a Vertiv™ Company is capable of precise flow measurement at the specified project static pressure, enabling accurate sound test measurements for air handling units. Energy Labs, a Vertiv™ Company’s testing facility is capable of:

- Testing air handling units, up to 75,000 CFM, with calibrated and certified flow stations

- Variable speed make-up fans allow balancing to any pressure from 0 to 10”

- High Accuracy barometric, temperature and pressure instrumentation in accordance with AMCA 210 and 300 requirements

- Power Analyzers for accurate power and harmonic data measurements

- One of the largest dual reverberant chambers (82,750 / 45,850 ft3) in the business that allows simultaneous measurements of supply and return sound levels of large air handling units.

Leakage and Deflection Testing

Leakage and Deflection Testing

All Energy Labs, a Vertiv™ Company air handling systems can be factory tested to verify air leakage performance by using one of three calibrated leak testing station. These stations measure leakage to SMACNA performance levels.

Minimizing Leakage is important as:

- Air leakage decreases unit efficiency and increases operational costs

- Can cause condensation formation at the leak site increasing unit casing corrosion and water puddling

Energy Labs, A Vertiv™ Company's Aero Acoustic Lab

Energy Labs, A Vertiv™ Company's Aero Acoustic Lab

Energy Labs’ state-of-the-art recirculating Aero Acoustic Laboratory offers the simultaneous measurement of airflow, static pressure, power consumption, and inlet and outlet sound power levels; all to the accuracy required by AMCA 210 and 300 standards.

System curve modulation takes place inside the Airflow Measurement Station, which is acoustically isolated from the sound chambers. Large reverberant chambers yield low air velocity across the microphones and heighten accurate sound measurement at frequencies of 50 Hz and below.

High Efficiency Air Foil Fan Wheel

Our OptiFLow™ fans feature a fully welded, aluminum airfoil blade design for high operating efficiency and quiet operations, with the characteristic non-overloading horsepower curve. These fans provide very stable operation due to a steeply rising pressure curve and are available to meet AMCA Class II or Class III requirements

All fans, whether in single or multiple fan configurations, are mounted on spring isolators with seismic restraints, and are available to satisfy the most stringent seismic requirements of the International Building Code.

Unique in the industry, our full range of fans are licensed to bear both the AMCA Standard 210 seal for air performance.

Our spring isolators are designed with seismic restraints as a standard feature.

Benefits of Multiple Fan Configurations

Optimum Energy Efficiency

Offering optimum size fan and motor selections that keep fan diameters larger; utilizing higher operating efficiency fan motors; and eliminating energy robbing bearings and belt drives all contribute to optimum energy efficiency

System Redundancy

For critical applications that must be capable of 100% airflow at all times, multiple fans ensure 100% air flow even when any one fan is inoperable

Improved Acoustical Performance

Fans in multiple fan systems will operate at a higher RPM than on large single fan in an identical application, resulting in reduced sound levels in the hard to attenuate 1st and 2nd octave bands.

Reduced Unit Footprint

Smaller fans require less cabinet length to house their assemblies, and they require less space both upstream and downstream of the fans while still ensuring good air distribution and efficient operations. However, the space cannot be reduced below what is needed to provide proper service access. A four fan system can typically reduce unit length by 4’ or more when compared to a single fan system.

Unit Construction

To ensure the highest quality and compatibility, we manufacture critical components including coils, fans dampers, louvers, and electrical control panels. This unique capability allows us to maintain the highest level of quality while providing the benefits of true single-source responsibility to our customers. An added benefit is the elimination of potential delays and errors caused by component delivery and design issues.

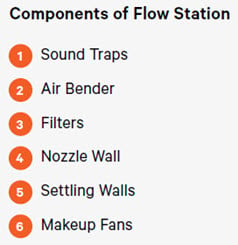

Base Frame

Base Frame

Unit base frame designed for optimal strength and rigidity to reduce unit deflection during handling, installation, and operation. The design includes cross-members at critical junctions to support internal components such as fans and coils or meet site seismic requirements.

- Design

- Welded

- Bolted

- Material

- Carbon Steel

- Stainless Steel

- Aluminum

- Finish

- Painted

- Not Painted

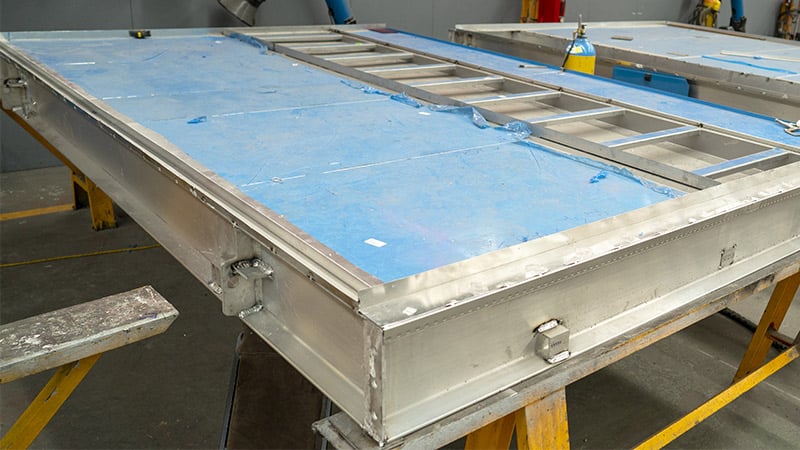

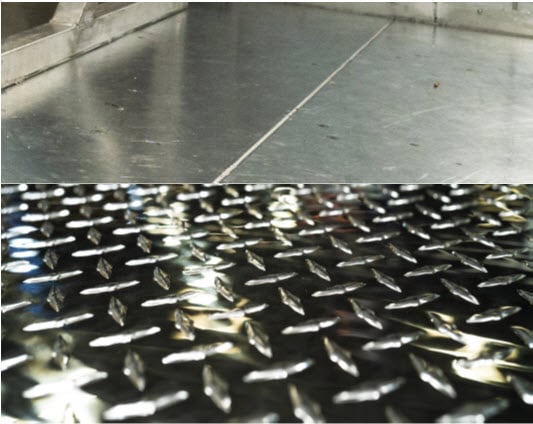

Unit Floor

Unit Floor

Fully welded, leak proof floors are selectable options, with polyurethane spray foam insulation and constructed to provide a safe and robust working area inside the unit. Condensation pans and floor drains are optional to remove standing water from air path.

Available material options include:

- Floor Material

- Painted Steel

- Stainless Steel

- Bright Galv. Steel

- Aluminum

- Anti-Slip Surface

- Tread Plate

- Paint

- Underliner

- Galv. Steel

- Stainless Steel

- Aluminum

Cabinet Construction

Cabinet Construction

Includes extensive offerings in insulation, material, and additional options. Insulation options include foam, fiberglass, or mineral wool. Cabinets can be constructed using painted steel, stainless steel, or aluminum. Additional options include incorporating thermal break and/or moisture resistance.

Cabinets are designed to meet a wide array of project specific requirements:

- High seismic levels or unique structural requirements

- Thermal and flow efficiency (EER)

- Architectural and color requirements

- Pressure and leakage as defined by SMACNA

- Indoor and outdoor installation

- Corrosive ambient

- Corrosive ambient

Roof Construction

Roof Construction

Roof designs for both Outdoor and Indoor applications:

- Outdoor Installation:

- All roof panels feature a bolted standing seem construction to ensure a leak-tight assembly

- Drive cleats cover all roof panel seams

- Roofs are sloped to ensure proper water drainage

- Indoor Installation:

- All roof panels are manufactured and assembled to promote a low-profile construction

- Seams or bolted and caulked to promote a low leak design

Door Construction

Door Construction

Access doors are double-wall construction, matching the exterior and interior construction materials and insulation thickness used in the section. Access doors include:

- Door Mounting

- Mounted in a rugged extruded aluminum frame

- Heavy-duty hinges with corrosion resistant hardware

- Insulation

- Foam, Fiberglass, or Mineral Wool

- Additional Options

- Thermal break doors and frames

- View Windows

- Lockable Handles

- Test Ports

- Fan safety interlock

Internal Components and Options

Airflow Conditioning

Airflow Conditioning

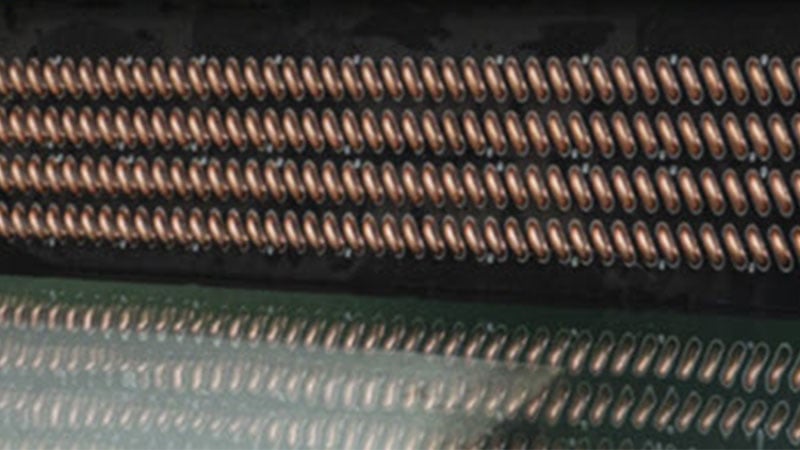

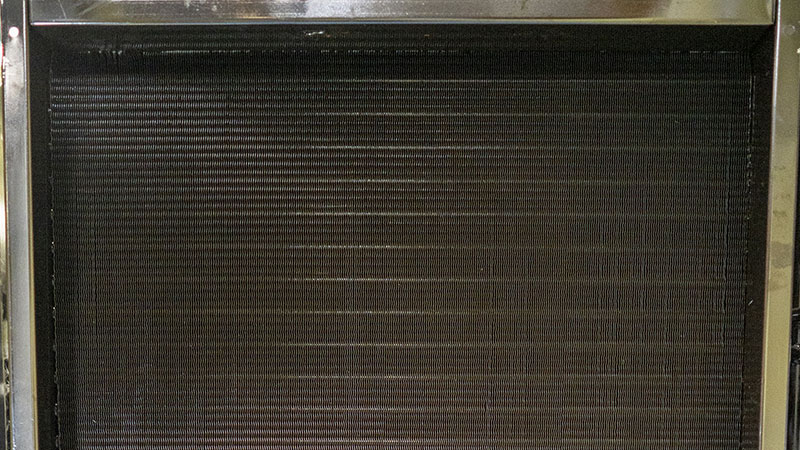

Coils

We offer, design, and manufacturing a robust line of coil solutions including Chilled Water, DX, Hot Water or Steam Coils. Coils are built using the following materials

- Copper tubes of various diameter and gauge, with fins made of Aluminum or Copper material (ElectroFin Coating Available)

- Brazed or bent return bends options available, based on tube thickness

- Stainless steel casing standard on all cooling coils

- Coils >48” tall include a unique drain pan design built into fin pack

Heaters

Wide variety of heating solutions to meet customer’s requirements. Offerings include:

- Steam coils

- Hot water coils

- Indirect Fired Gas Heat

- Integral face and bypass dampers

- Other solutions can be provided with support of a Systems Applications Engineers

Humidifier

Steam injection manifolds can be provided to meet humidification requirements. Each section is supplied with factory installed distribution grids and stainless-steel drain pans to ensure safe operation and quality airflow.

Fan Systems

Fan Systems

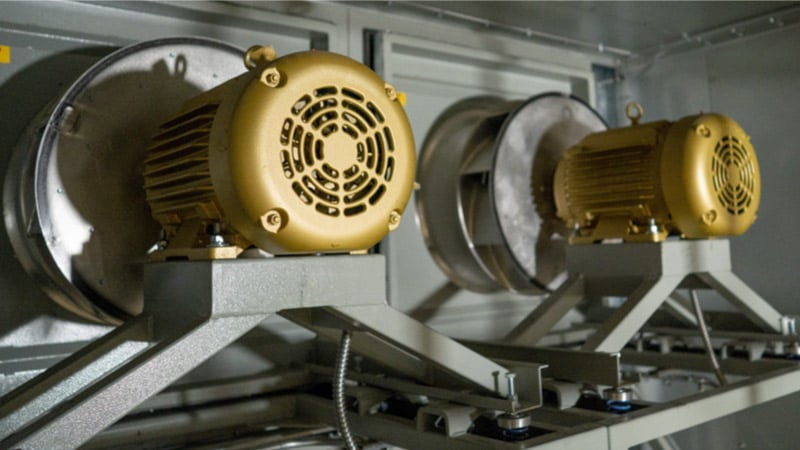

Optiline HE Fan Systems

Optiline HE fans feature a fully welded aluminum airfoil blade design for efficient and quiet operation, available in a single or multiple fan configuration. Multiple fan configurations are frequently the best choice as they offer many valuable system benefits, including:

All fans, whether in single or multiple fan configurations, are mounted on spring isolators with seismic restraints, and are available to satisfy the most stringent seismic requirements of the International Building Code.

- Optimum Energy Efficiency

- System Redundancy & Reduced Service Downtime

- Improved Acoustical Performance

- Reduced Unit Footprint

Spring Isolators

Spring isolators with seismic restraints are mounted on all Optiline HE Fan Systems, capable of satisfying OSHPD and IBC requirements (others can be reviewed).

Fan Wheel

All Optiline HE Fans include a fully welded fan wheel, that is designed, built, and paired with a motor to match the project ambient and airflow requirements.

Flow Trac™

The Energy Labs, a Vertiv™ Company Flow Trac system measures air flow rate. Using the fan inlet cone as a calibrated nozzle assures the airflow and sound levels are not affected by obstructions in the flow path.

IAQ Options

IAQ Options

Modern buildings require ventilation rates to comply with ASHRAE Standard 621 as well as Good Indoor Air Quality (IAQ). Poor IAQ has been directly associated with “sick-building syndrome”, which can result in high illness rates, absenteeism, reduced productivity, and employee turnover.

IAQ Condensate Drain Pans

- Double-sloped design to prevent standing water

- Pans completely cover the coil plenum section width

- Pans are insulated with spray foam

- Fully tig welded construction

- Stainless steel drain connections and piping

- Available in threaded NPT connections

Surface/ Airflow Sterilization

A flexible and effective offering for surface and airflow sterilization

- Surface Sterilization

- UVC irradiation provides low intensity, full-time irradiation of the coil and drain pan surfaces

- Proven effective as a low energy demand, disinfectant for surfaces

- Airflow Sterilization

- Solutions, such as bipolar ionization, can be reviewed and supplied

- Work with a Systems Applications Engineer for more details and design support

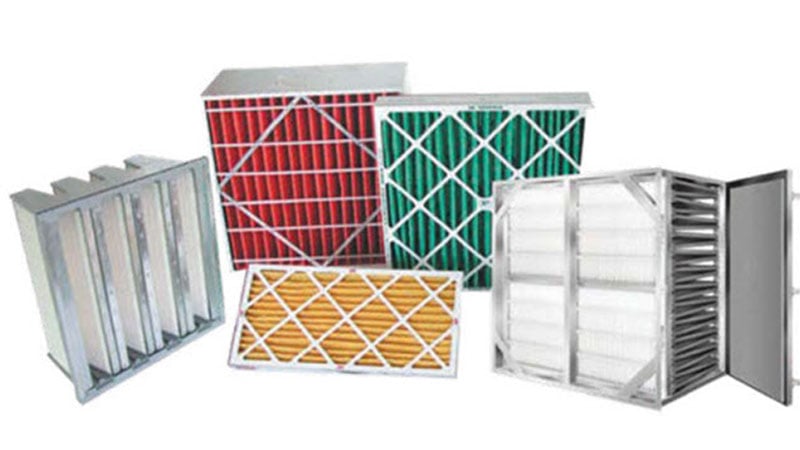

Filters

Filter options to meet project requirements, including:

- Panel filters

- HEPA filters

- Carbon filters

- Electronic filters

- Roll filters

- Bag filters

All filters and filter frames are selected and designed to allow for service access.

Electrical Component Options

Electrical Component Options

Factory Installed Controls

The Vertiv iCOM 3 control system platform is offered as a standard. Requests to integrate other Building Automation System supplier’s controls systems can be reviewed. Most, if not all, controls components are factory installed and tested, which reduces commissioning time and cost.

- Control device | Sensors | Actuators | Flow Dampers | Etc.

- Most, if not all, wiring is pre-routed in conduit/trough per Energy Labs, a Vertiv™ Company standards

- Point-to-point wiring diagrams provided with unit drawings

- All penetrations are made and sealed in the factory

Fan Speed Controls

Fan speed control offers the most efficient method of varying air volumetric flow. The ability to control fan motor speed allows customers to optimize the design while maximizing energy savings through dynamic cooling loads. Options include:

- Variable Frequency Drives for Non-EC fan arrangements

- Single drive per fan motor

- Singe drive per fan array (multiple fans)

- EC fan arrangement

- Fan/motor arrangements are supplied with an integral speed control device

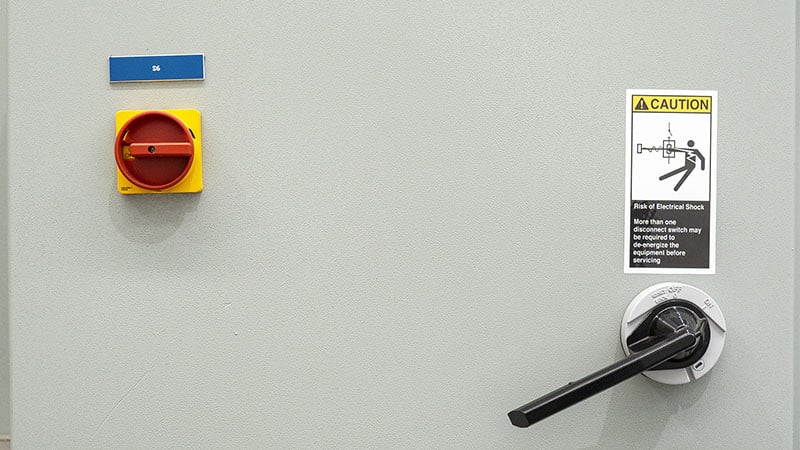

Single-Source Power Panel

To simplify the installation and improve quality of the electrical supply, single-source power panels are included as a standard. This allows field connections to be minimized to a single power connection, reducing site wiring, and testing efforts.

- Features:

- Disconnect Switches

- Fuses and relays

- Starters

- Transformers

- H-O-A Switches

- Pilot Lights

- Ratings:

- NEMA 1 | 3R | 12

- Listings:

- UL508A

Airflow and Sound Control Options

Airflow and Sound Control Options

Dampers and Louvers

High performing low leak dampers and outside air louvers are available as needed. The low leak dampers and air louvers are designed in accordance with AMCA 511 and rated for pressure drop, leakage, and water penetration.

Airfoil design includes

- Aluminum airfoil to minimize pressure drop

- Minimizes noise levels by reducing air movement friction across the blades

Low leak design features

- Neoprene blade seals

- Stainless steel side seal

- Overlapping blade edge for secure shut off, preventing damper over travel

Construction

- Galvanized steel frames

- Robust linkage systems

Options

- Optimum Energy Efficiency

- Factory mounted actuators

- Locking quadrants

Sound Traps

Sound traps can be designed for any application with noise restrictions. Available sound traps include:

- Low Frequency traps

- sound traps

- Sound traps with Mylar film covering the fill

- Packless sound traps, for applications where fiber airstream contamination is a concern

Energy Recovery Options

Energy Recovery

Modern buildings require ventilation rates to comply with ASHRAE Standard 621 as well as Good Indoor Air Quality (IAQ) to keep occupants happy and healthy.

- Poor IAQ has been directly associated with “sick-building syndrome”, which can result in high illness rates, absenteeism, reduced productivity, and employee turnover.

The challenge with Energy Recovery is balancing the efficiency gains with the energy consumption. To aid with this selection, Energy Labs, a Vertiv™ Company experienced applications engineers can help customers select one of the AHRI listed energy recovery systems to ensure customers get the performance required. Energy Labs, a Vertiv™ Company offers the following AHRI listed energy recovery solutions:

- Poor IAQ has been directly associated with “sick-building syndrome”, which can result in high illness rates, absenteeism, reduced productivity, and employee turnover.

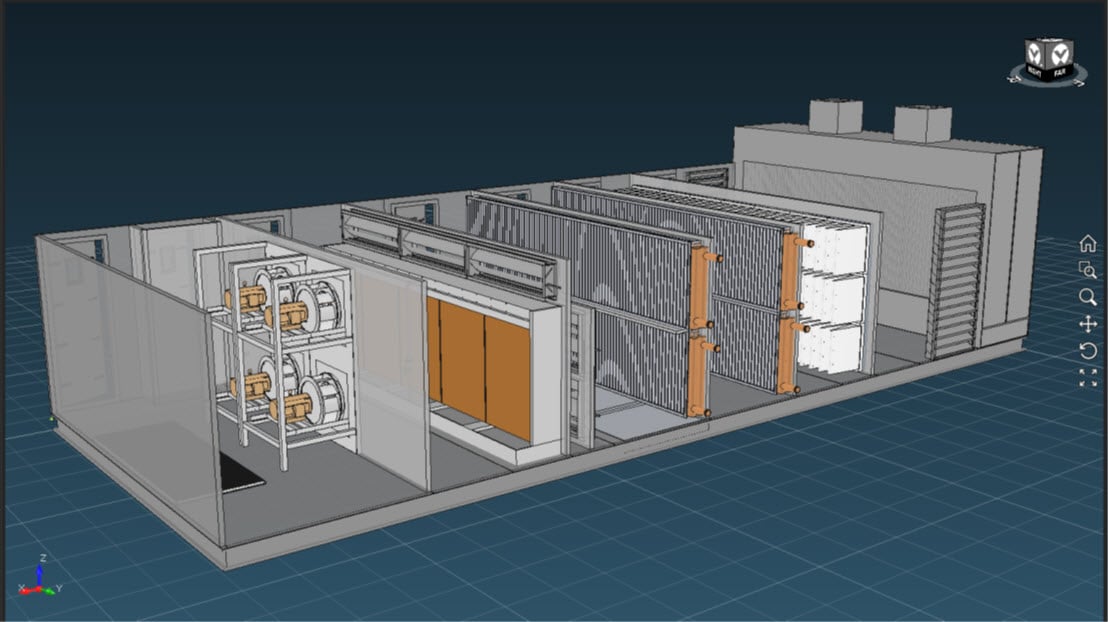

Vertiv Thermal Designer (VTD)

The Vertiv™ Thermal Designer configuration software is available to all Energy Labs Sales Representatives. Providing the ability to generate detailed system designs and budget pricing for most unit configurations, remotely or from the office. The software allows interactive, real-time evaluation between the Systems Application Engineer and the Sales Representative, providing optimum selections while saving valuable time. Critical design and pricing information provided by the software allows real-time analysis:

- 3D System Design Environment

- Ongoing visual equipment design evaluation to verify selected features

- Built-in guidelines accelerate selection of coils, fans & other components

- These guidelines work in the background to help avoid design errors

- Unit Physical Details

- Ready review to satisfy critical space and access limitations

- Weight limitations and possible use of alternate, weight saving materials

- AutoCAD drawings for incorporation into design documents

- Technical Details

- Review key electrical data

- Review alternate fan selections to best match design goals

- Review alternate coil selections to best match overall performance goals

- Pricing Details

- Review budget pricing

- Review alternate component options to evaluate cost/benefit relationship